Offshore Round Cage

As demands for aquaculture products rises, so is the demand for more durable cages for use in offshore waters. Aquatec cages are build on the foundation of extensive knowledge in HDPE pipe extrusion and large HDPE component injection since 2008. Over the years, our capacity and capability have grown in order to accomodate the ever increasing demands of our customers, and we have delivered over 15.750 cages in Indonesia, Singapore, Malaysia, Philippine, Taiwan, China, Maldives, and Ghana.

Innovative Engineering

Aquatec provides a series of round cage designed to withstand the extreme weather of offshore waters with sea waves up to 5 meters.

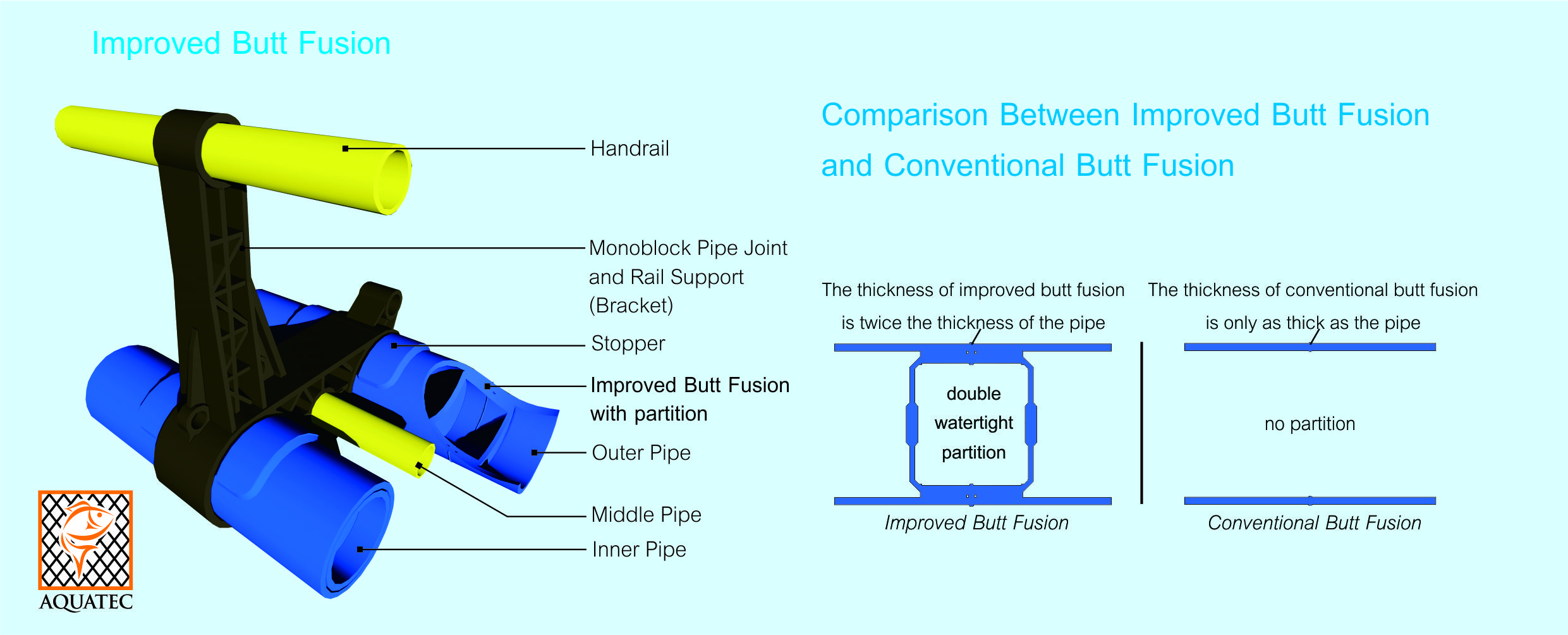

In order to achieve such engineering feat, we implemented a refined method of the butt fusion connection to our pipes in what we called Improved Butt Fusion, that has been patented in many countries around the world.

Improved Butt Fusion is a butt fusion with the thickness of the connection up to twice the thickness of the pipe, controlled with precision timing and pressure, resulting in a connection that is much stronger than the pipe itself. This method practically eliminates the risk of pipe connection failure. Furthermore, a number of watertight partition is installed inside the pipe to divide the pipe into several separate watertight compartments, which greatly improves the safety and durability of the pipe. With these implemented, there is no need to install bulky styrofoam inside the pipe, therefore improving the buoyancy of the pipe and giving the cage environmentally friendly status.

Great Product Starts With the Best Material

To cut costs, many suppliers use low quality recycled PE material with black color that look fine at a glance. The truth is, recycled PE material has much lower tensile strength than virgin PE and will break in a few years of use. Aquatec only use virgin High Density Polyethylene (HDPE) with PE100 category, added with Anti UV masterbatch to ensure optimum tensile strength and durability.

To prove this, our products come in bright colors such as blue and yellow, that can only be achieved using virgin PE material. As an added benefit, bright colors reduce the heat absorption of sunlight, making our cage and handrail relatively cool and comfortable for work.

Unmatched Structural Integrity

Pipe Joint and Rail Support (or Bracket) is the backbone of an offshore cage, as it directly correlates to the lifetime of the cage on the sea. Therefore, we do not compromise in making this component. Unlike many suppliers that produce the component using cut pipes welded with hand tools, Aquatec produces its Pipe Joint and Rail Support using high capacity HDPE injection machine in order to make it into a compact, one piece component. With cross branching structure that provides unmatched structural integrity, the result is a monoblock Pipe Joint and Rail Support that can withstand the heavy abuse of the sea. The absence of welding eliminates any weak points, making it the ultimate solution for your cage.

Monoblock Pipe Joint and Rail Support (Bracket)

Made using HDPE injection machine, the Pipe Joint and Rail Support is a compact one piece (monoblock) component that is used connect pipes and act as a support for handrail. Cross branching structure gives optimum structural integrity for heavy duty use.

Specification Table

Stopper

Stopper acts as a brace that is fused with the pipe to prevent Pipe Joint and Rail Support from sliding.

As important as it is to use durable pipe joints and rail supports, it is equally important to keep those components in place through constant sea water movement. To complement our monoblock Pipe Joint and Rail Support, we secure each of them with Stoppers. Our Stoppers use the same HDPE material as the pipe, and are fused to the pipe with electro fusion, making them inseparable from the pipe and securing them firmly in place. You can be sure that our monoblock Pipe Joint and Rail Support will not slide even in heavy storms.

Offshore Round Cage Illustration

Antibiofouling HDPE Pipe

Aquatec layered its HDPE pipe with antibiofouling and anti-UV HDPE. Antibiofouling prevents fouling on HDPE pipe, therefore maintenance efforts and costs associated with biofouling management will be greatly reduced. Anti-UV protects HDPE pipe from intense UV rays from sunlight and greatly prolongs product lifetime to more than 25 years. This technology is environmentally friendly. It is the first of its kind in the world and is available only with Aquatec.

Wide Cage Selection

We provide cages from 10m to 60m diameter, with HDPE pipe outer diameter (OD) ranging from OD 250mm to 630mm. For offshore use, we use Side Wall to Diameter Ratio (SDR) of 17 or thicker. You can consult our cage expert about which pipe best suited to your site condition.

Easy Harvesting and Net Cleaning

We know that raising the net for harvest and cleaning the net are two of the hardest tasks to do. With a little cost we can provide you with a mechanism to raise the net bottom frame to the surface without using a crane. Harvesting fish and cleaning the net has never been this easy! Consult our staff for the information about how it works and don’t forget to purchase it for your cage.

Predator Free Cage

For protection against predators, we have double net variant, where a second layer of net is placed outside the main layer with a certain distance to protect your fish commodity. The distance between the main layer and the outer layer not only protects against predator attacks, but also obscure predator’s vision that reduces the probability of attacks, reducing both the frequency as well as the damage predators can do.